Easy Handling

Low net weight, approx. 7 kg

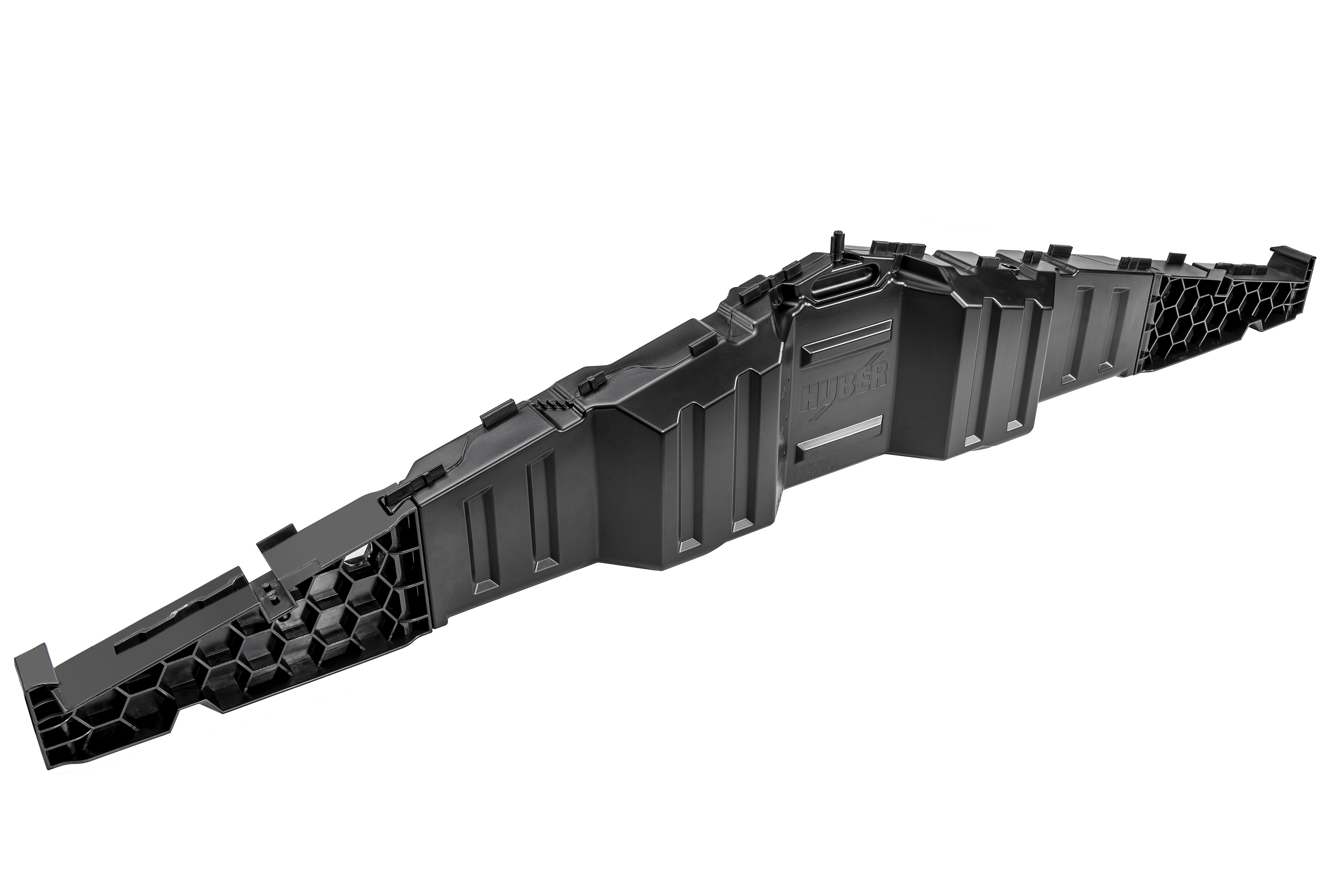

The PowerEdge Solar System is an innovative substructure for the professional and secure installation of photovoltaic systems on flat roofs.

Low net weight, approx. 7 kg

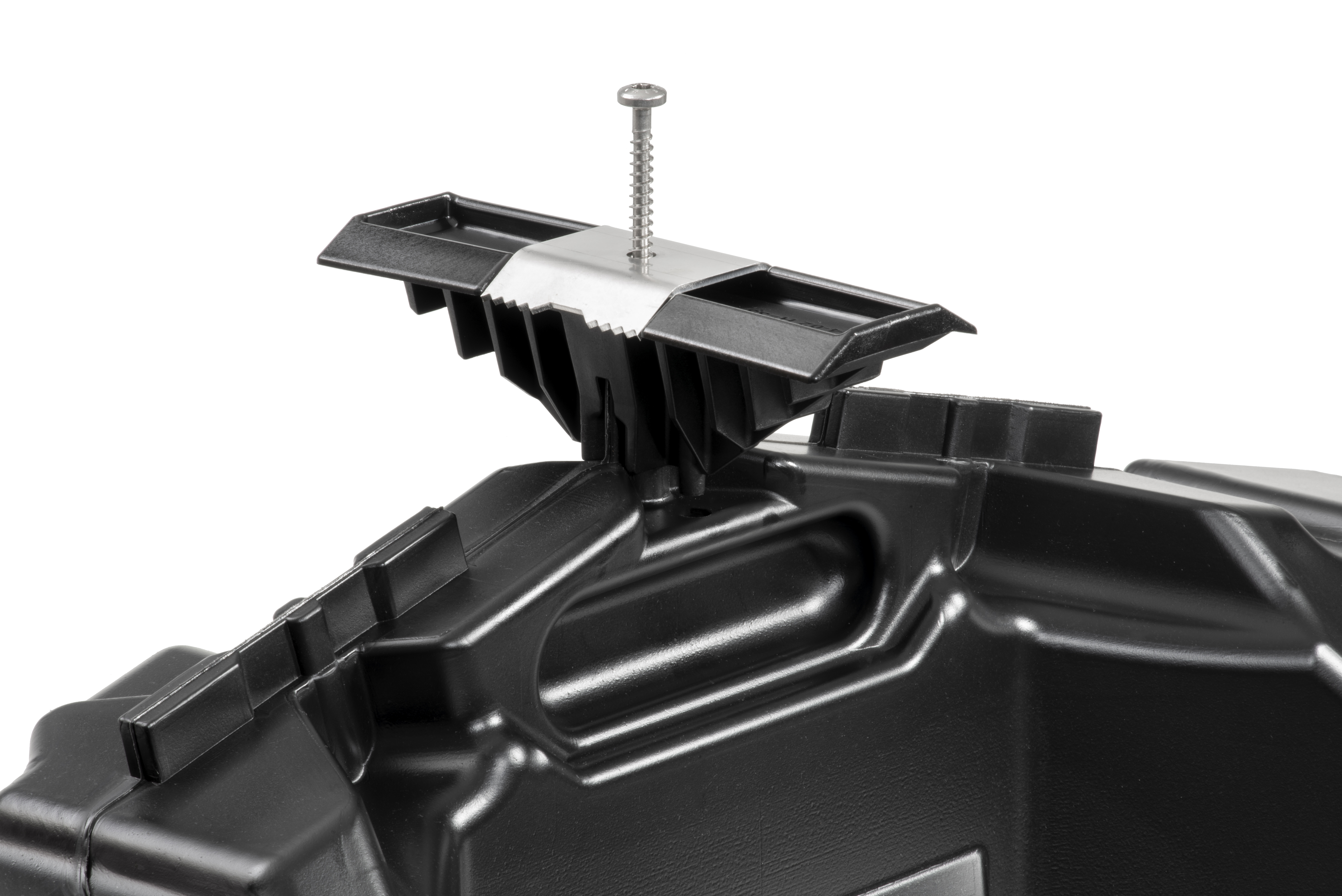

- Plug-in connection instead of screwing

- UV- and frost-resistant: tested from -30°C to +80°C

Based on a typical 100 kWp system with an aluminum substructure

- Total weight reduction of up to 70%**

- Easier transport and lifting

| Product Specifications | Values |

|---|---|

Permissible Roof Slope |

0° - 6° |

Module Orientation |

East / West |

PV Module Width |

1.129 - 1.136 mm |

PV Module Height |

29-30 mm |

Tilt Angle |

15° |

Material |

Plastic (HDPE with UV protection) |

Empty Weight |

Approx. 7 kg |

Max. Total Weight |

Approx. 47 kg |

Ballasting Medium |

Watter |

Temperature Resistance |

-30°C to +80°C |

Manufactured According to Standard |

ISO 9001:2015 Quality Management System |

Warranty |

20 years (prerequisite: professional installation and documented system maintenance) |

Application Area |

Flat roofs with: bitumen, membrane, green roofs, or gravel; balcony systems for terraces and garden installations |

Yes, absolutely! For membrane roofs, there are special aluminum-laminated protection mats that prevent the diffusion of plasticizers from the roofing material.

Yes, PowerEdge Solar can be placed directly on gravel. This eliminates the need for gravel cleaning and new roofing fleece. Even if the gravel is overgrown, that’s not a problem. However, it is recommended to trim back vegetation between the rows about once a year. If there is heavy plant growth, we recommend placing a garden fleece under the maintenance walkways. A plastic cover with the same purpose is currently in development.

The tilt angle is 15°. Other angles will only be offered if there is sufficient demand. However, 15° is a well-balanced choice: it offers high energy yield with minimal shading, and dirt, rain, and snow are less likely to accumulate. With a 10° tilt, you can gain approximately 0.8% more energy output using the same number of modules, but you’ll also need about 2% more space.

When the adapters are connected, the distance between modules is 60 mm, which is too narrow to walk through. That’s why it is recommended to regularly insert spacer elements between rows, increasing the distance to 145 mm — sufficient for walking between the modules for maintenance and cleaning purposes.

With the standard adapter, standard modules with a height of 1129 – 1136 mm and a module thickness of 29 – 31 mm fit on the PowerEdge Solar water tanks. The width is not critical for compatibility, but it must be known for layout and ballast calculations. For modules with different heights, suitable adapters can be ordered. Please contact your advisor in advance to coordinate this.

A 20-year warranty is provided, under the usual conditions of professional installation and documented system maintenance. PV modules typically come with a material warranty of 20–30 years. The expected lifespan of the PowerEdge Solar substructure, however, is significantly longer than that of the PV modules — and the system can be reused after module replacement.

Yes, the tanks have been thoroughly tested at temperatures ranging from –30 to +80 degrees Celsius and have passed the PV1200 climate test. The tanks feature grooves that absorb expansion and are UV-stable. No antifreeze is required.

Evaporation is minimal, and the tank is designed with a funnel and channel system that refills it with rainwater up to the pre-drilled fill level. Any excess water is automatically drained off, maintaining the optimal water level.

The maximum certified load per tank is 1,200 kg. This means that a system with standard modules can withstand up to 3,000 N/m². For alpine installations where higher snow loads are required, the maximum snow load can be increased to 6,000 N/m² by adding an extra tank in the middle. Please ensure that the PV modules themselves are rated for this load as well!

The PowerEdge Solar system has a closed side design, making it less sensitive to wind than many other substructures. It has been wind tunnel tested in accordance with EN 1991-1-4. For ballast calculations, this standard was supplemented with national annexes — in Switzerland, specifically SIA 261. The required ballast depends on several factors, including location, roof height, parapet height, friction coefficient, and the interconnection between modules.

Installation time has been measured multiple times, showing a time saving of 50–70% compared to aluminum substructures. With two people, it is possible to install 8 kWp of PV in just one hour.

Yes, the tanks are certified according to ISO 9001:2015 and come with a 20-year warranty. They are made from 100% recyclable HDPE plastic and produced using solar-generated energy.